How To Fix Low Frequency Problems - Panel (Diaphragmatic) Absorbers

Oct 16, 2023Low frequency issues are the biggest problem for soundproofing and acoustically treating a room. In this article I will discuss how to treat low frequency issues below 125Hz in your room using panel bass traps.

1) What Is A Diaphragmatic Panel Bass Trap?

Low frequencies below 125Hz are hard to treat with acoustic panels made from fiberglass batts. To treat these lower frequencies we need a different tool. The best tool for the job are pressure traps that use a closed air space to attenuate low frequencies. These traps are efficient at reducing low frequencies, but they have a narrow Q, meaning they only work in a narrow frequency band. For this reason I only recommend building these traps after you have extensively treated your room with velocity traps aka insulation with fabric over it.

The bass trap I will be discussing has many names ranging from diaphragmatic absorber, low-bass panel trap, resonant absorber and so on, but the theory remains the same. These traps use an enclosed box with a calculated airspace depth to create a resonant chamber that attenuates bass at a specific frequency.

To calculate our panel mass and depth we need to use the following formula to ensure our bass panel trap will attenuate the correct bass frequency. The formula is as follows:

f (frequency) = 170 / square root of (mass x depth)

*For metric change 170 to 60 -

m = mass is in pounds per square foot of resonate panel

d = depth in inches

Now the easiest way to calculate potential panel depth and materials is to create a spreadsheet for plywood thicknesses and depths and see what materials you need and depth you need to attenuate the correct frequency.

Adding loose glass fiber to the back of your panel will increase absorption, but it also will move the peak absorption lower down the frequency spectrum.

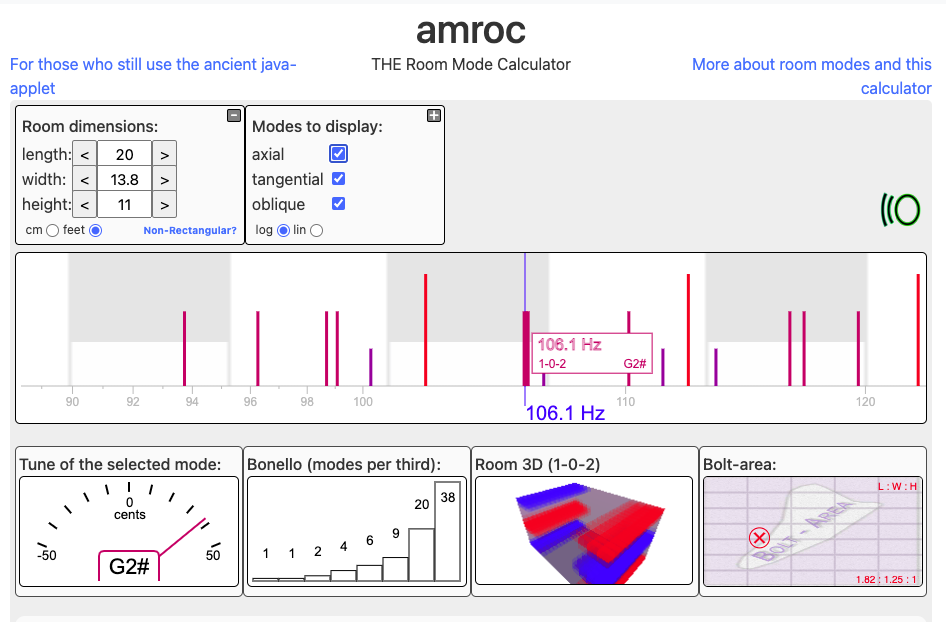

These panels are only effective when placed at a pressure maximum in your room for the desired frequency you are trying to treat. This means that you need to find out where a room mode is ringing out in your room and place the panels on that wall or ceiling. To do this you can use a calculator like, AMROC online to see where room modes in your room are, or you can play a sine wave through your speakers and walk around the room noting where the bass note sounds louder or completely gone. The places where the bass notes are louder is a pressure maximum and is where you should place a trap.

Lastly, it is important to make each panel absorber at least 5 sq/ft to have an affect on the room. You will need to place one or two in your room to and re-measure your rooms response to see how many absorbers you will need.

2) So What Frequencies Do You Need To Treat?

This is a good question. We know we have bass problems in our room, but now what? First, you need to measure your room. You must use REW or equivalent room software and a measurement mic that is properly calibrated to measure your room. This will show you what frequency problems you have in the low end. Let's use my studio as an example.

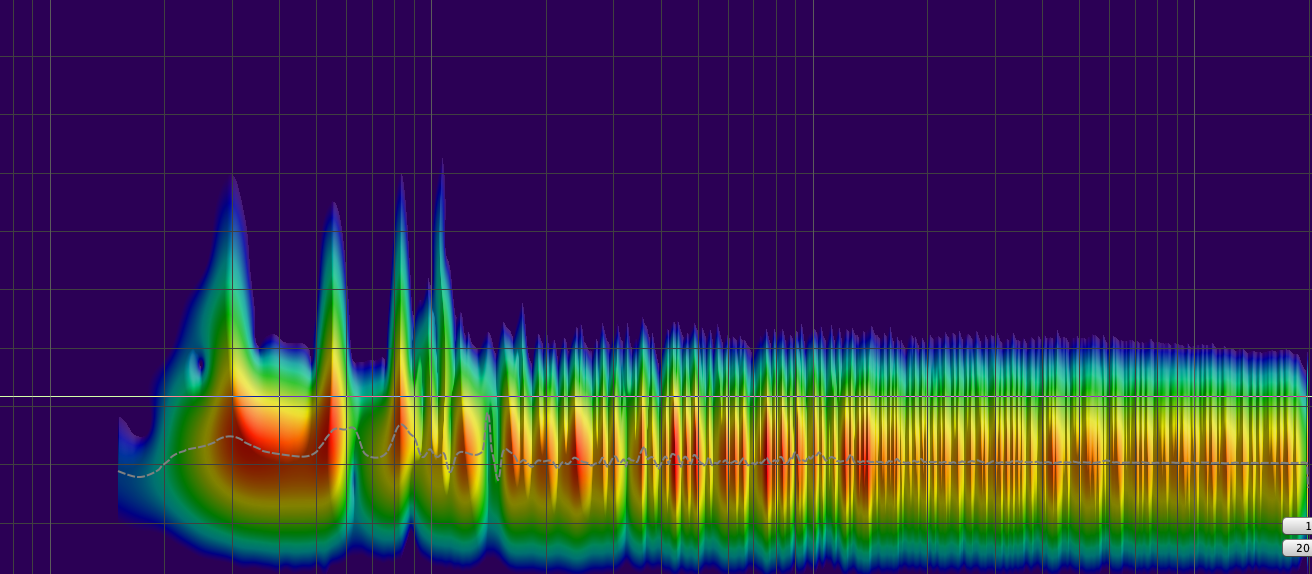

Below is a picture of my REW results for the spectogram. I like to look at the spectogram because it shows which room modes are "ringing" out in my room at my listening position.

Notice how most of my room is flat in the upper frequencies, but down low we get those flame like peaks. Those are my room modes ringing out where I mix. This will make my bass a bit muddy to hear since those frequencies don't decay at the same rate as ones nearby.

The solution is to build traps that target those frequencies. It is analogous to a sniper rifle vs a shotgun approach. The panel trap can isolate those problem frequencies.

So, the first ring out is at 106 Hz. Let's now look at where to place that panel.

3) Where To Place Your Panels

As I mentioned before, you can use AMROC or sine waves to find your pressure maxima at 106Hz in my example. For this example I will use AMROC to show you where that frequency modal issue is at a maximum.

That 106Hz frequency is a tangential and oblique mode that is maximul at the blue and red areas on the Room 3D visualizer on AMROC. AMROC plays the tone when you hover over it so I also could hear a huge peak in the middle of my back wall. To treat this frequency I would build probably build a 2x4' trap and place it in the middle, bottom or top of my back wall.

Let's now look at what mass and air depth I need to treat that 106 Hz frequency.

4) Calculating Box Depth

Based on the math here we know that the thicker the plywood the thinner our box can be. I like saving floor space so I was going to use 19/32 OSB Sheathing. This is affordable and readily available at my hardware store.

19/32 OSB weighs roughly 2 psf. This means we have to do a little algebra to solve for the depth.

106hz = 170/ square root (2 * d)

square root (2*d) = 170/106

2*d = 1.6 squared

2*d = 2.56

d = 1.28"

The answer ends up being 1.28 or 1 9/32".

Yay! Okay so we have our box depth, now let's design the box.

*it is a good idea to weigh your panel before building just to double check the math is correct.

**You could use 2 lb MLV and absorption would be greater, since a limp mass membrane will add to absorption through damping. I might do this depending on cost and availability of 2 lb MLV.

5) How To Build The Panel

Okay we did our room analysis, we did some math, we got our panel material, now it is time to build this bad boy. Here is a mock up I did of how I would build a trap to have a center resonating frequency of 60hz.

With a 106 Hz panel like in our example the box is so thin that I would forgo the insulation or use really thin insulation. With lower frequencies you can use the Corning 703 or a similar insulation to help improve absorption.

Make sure to acoustically seal all corners with your MDF to make sure the box is truly airtight. When finished you can test the box using a sign wave at the resonant frequency you were hoping to absorb. Ideally you will feel the panel vibrate at that frequency.

Conclusion

Bass trapping is much more labor intensive than velocity traps, but you can really tighten up your low end if you put them in the right spot and build them correctly. In the end you may want to buy a pre-made panel. Either way, remember to fully treat your room with normal acoustic panels before attacking your low end.

Are you ready to move from planning to building?

Book a Soundproof Planning Call to determine whether your studio is feasible, what it will realistically cost, and what path makes sense for your space.